Conrad E-31 Etching Press Maintenance Manual

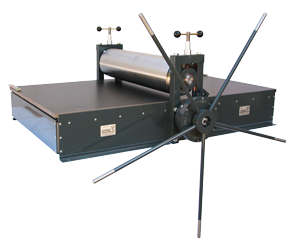

Unpacking your Conrad Etching Press.

Your Conrad etching press is shipped on a custom skid/palate and enclosed in a heavy, corrugated box. This box is stapled to the palate using furring strips. If your press is shipped with an enclosed star-wheel, you will need to open the top of the box and remove the enclosed star-wheel before proceeding. Take the star-wheel out of the box and set it aside until after the press is set up. If your etching press shipped with a Conrad stand/workbench or felt blankets, both will be enclosed in the box and attached to the palate. After you remove the enclosed star-wheel, stand, and felts, you can use a pry-bar or crowbar to remove the stapled furring strips from the palate. After the strips are removed, you can easily lift the box off the palate and press

After your press box is removed, your press can be unbolted and removed from the palate.

Setting up your Conrad Etching press.

Conrad E-31 Clearance Dimensions

Before you try to set up your Conrad E-31 Etching press, make sure your studio has enough room. The Conrad E-31 measures 41" x 54". You must also allow 20" on either sided of the press for the bedplate to travel. You will also want to leave 20" of clearance between the back of the press and the wall.

Bolting your press down.

Once your Conrad Monotype press is unbolted and removed from the shipping palate, your press can be bolted to your Conrad Etching press stand/workbench or another suitable table. The Conrad Etching press stand is custom made to fit your Etching press and provides the optimal support for your press as well as additional space for your inks and other equipment. The Conrad E-31 bolts directly to your press stand. Please see the Etching press stand assembly page for more information about assembling your Conrad E-31 Etching press stand.

If you mount your press on a table or bench other than the Conrad Etching press stand, be sure it is sturdy enough to support the weight of the 800 lbs. Conrad E-31 press as well as the strain of printing. We recommend fastening the press down with screws or clamps. However, the press is heavy enough so that this is not necessary except under the most extreme printing pressures. If the surface on which the press sits is warped or otherwise uneven, place cardboard shims at the four corners under or near the hold-down fastenings to prevent twisting the base of the press where the fastenings are tightened.

Etching Press Stand Assembly

If your press was purchased with a steel stand, follow the stand assembly instructions and place on a level floor. Use a bubble level to level the stand before bolting your press to it. See that all legs are in contact with the floor, and then tighten all the bolts securely. You may bolt the press to the stand with the four 5/16 inch bolts used to bolt the press to the shipping palate.

Setting up your Etching Press

After your press has been unboxed and bolted to its stand, you are ready to set up your etching press. Your press is shipped with protective material between the upper roller and the to prevent damage to the bedplate from vibrations during shipping. Simply raise the upper roller and remove the protective piece of Masonite before printing.

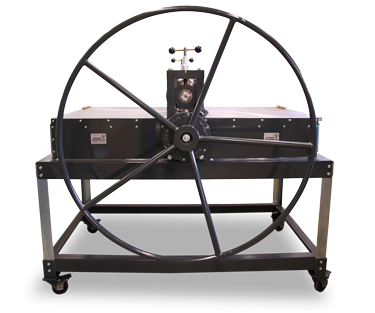

Installing an Open spoked Star-Wheel

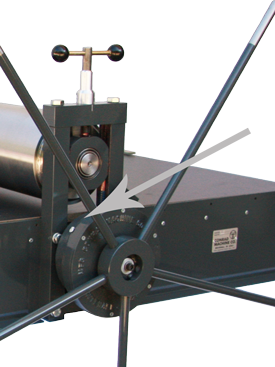

If your Conrad Etching press has a open spoked star-wheel, you will need to install the spokes once the press is set up. Your Monotype press' open spoked star-wheel hub will already be installed on the drive shaft. You will have to install the spokes in the hub. Simply take your spokes and screw them into the star-wheel hub until tight.

Installing a Enclosed Star-Wheel

If your Conrad Monotype press has a enclosed star-wheel, you will need to install it. After your press is completely set up, you can remove the setscrew that is in the hub of your enclosed star-wheel. Now the enclosed star-wheel is ready to be installed on your press. Take the star-wheel and line up the hub with the key of the drive shaft of the lower roller. Slide the star-wheel hub on the shaft and screw the setscrew in tightly.

Remove Packaging

Your etching press ships with a protective sheet of Masonite between the upper roller and the bedplate. Simply, loosen the pressure screws to relieve the tension of the upper roll on the bed plate and pull the Masonite out of your press.

Ready to Print

Now your press is all set up and ready to print!

Conrad Etching Press Maintenance

Lubricating your Etching Press

Bearings

Your etching press rollers are mounted on maintenance-free, sealed bearings. Since these bearing are lubricated and then sealed, you will never have to oil or grease them for the lifetime of your press.

Auxiliary Rollers

The auxiliary rollers are made of high impact rigid PVC (polyvinyl chloride) plastic and do not normally require any lubrication. However, a drop or two of light oil periodically applied will prevent the steel axles from rusting if they are subjected to moist conditions. Simply apply a drop of light motor oil to each auxiliary roller every other month.

Geared Drive

If your press has a gear drive, you should oil the gear drive once every five to six months. Only a small amount of oil is required because the gear housing is closed. Simply take an oil can filled with standard 30-weight motor oil and squirt one to two full squirts in the oil hole located on the side of the gear drive housing. Also on a gear driven press, the upper roll needs to be greased once every six months on the drive side where the shaft rotates in the drive stop bar with petroleum-based grease.

Pressure Screws

The pressure screws and the upright columns should be kept coated with a light grease applied with a small paint brush to prevent corrosion and to assure smooth operation.

Maintaining your Etching Press

Polishing Rollers

Keep your etching press clean and away from water. Try to keep water from coming into contact with the roller. If your Conrad Monotype press does not have chrome rollers, you may want to keep a light coating of oil on the exposed steel surfaces. You can accomplish this by keeping a tacky cloth, lightly oiled rag, handy. At the end of each day, wipe down the exposed steel surfaces including the rollers. Make sure to wipe off any excess oil on the roller before you begin printing, so the oil doesn't interfere with your printing or stain your felts.

As you use your press, the rollers will gradually become dull and stained. Don't worry; light staining or rusting on the surface is fairly common in humid and will not affect the proper operation of your press. You can clean, polish, and remove discoloration on your press rollers with fine steel wool or "scotch brite" pads. If you are going to store your press for any extended period of time, we recommend putting some type of oil-based preservative on the rollers to keep them from corroding and rusting while in storage.