Artist/ Printmaker

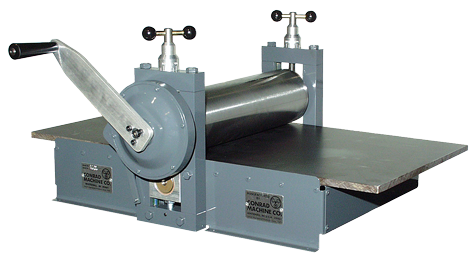

Most of the small Etching Presses being built today are not built to the same standards as large professional presses. Inadequate gearing, or no gearing at all, and unavailability of desired options are probably the greatest drawbacks of most small Etching Presses. When Conrad Machine Company designed the E-12 and E-15 Etching Presses, we gave them the same professional features and options that are available on our large professional presses. We offer an extensive line of options, so the printmaker can purchase exactly what he needs. Our presses are fully customizable, so you can get exactly what you need.

Etching Press-

Planetary reduction drive

The most remarkable feature of the E-15 etching press is the Planetary reduction drive. Torque from the 10 inch throw aluminum hand crank is multiplied in the fully enclosed geared planetary reducer. The ideal 6:1 ratio to provides smooth and easy operation under the heaviest pressure. This type of press drive, developed by Conrad Machine Co. in 1959, is a proven design concept. The Planetary reduction drive has provided trouble free service over the past 50 years on thousands of etching presses, ranging in width from 12 inches to 50 inches.

Etching Press Base and Frame

The base of the press is formed of 16 gauge electrogalvanized sheet steel. The steel sheet is riveted together to form a sturdy box section that is resistant to twisting and tipping. Unlike many of our competitors' presses, the base extends the full length (30 inch) of the bed plate.

The Vertical Frame is constructed of one inch square, high tensile aluminum. The aluminum provides maximum strength with a minimum weight. The frame, pressure screws, bearing blocks, and lower roll adjusting screw all share a common centerline to eliminate twisting or bending of the frame under high printing pressure.

Etching Press Bed plates

There are many different views of what material makes the best bed plate; to a large extent, we feel it is a matter of personal preference. Therefore, we offer three different types of bed plate material. The standard bed plate is made from half inch thick Benelex. Benelex is a high density lignin-resin laminate, having a compressive strength of 29,000 P.S.I. This material is only a sixth the weight of steel. The optional bed plates are steel or aluminum alloy. Please see the options or pricing section in our catalog for more details about optional beds.

Etching Press Rolls and Bearings

The Upper Roll is spring counter balanced to maintain height adjustment whether or not the roll is in contact with your work. We only use large 1.5 inch diameter roll bearings. These high quality bearings are rated at well over five times the maximum pressure encountered in normal printing! Both the upper and lower rolls on the E-12 etching press are precision machined from three inch diameter, solid steel. The E-12 rolls assure precise and deflection free printing. Options include an oversize 4.5 inch diameter upper roll or 3 inch diameter solid Aluminum Alloy Rolls. The E-15 etching press comes with a 3 inch diameter solid steel lower roll and a 4.5 inch diameter steel upper roll.

Etching Press Micro-Gauges

Most small presses are not even available with Micro-Gauges. The small presses that do offer micro-gauges use a scale type design that is inferior to a barrel-thimble design. Conrad Machine Co. offers a barrel-thimble Micro-Gauge that is calibrated to .005 inch per line. This means that you can adjust each pressure screw by about the same thickness as a human hair! The Conrad Machine Co. Micro-guages are the very best in the printmaking industry.

Etching Press 25 Year Warranty

All Conrad Machine Co. Presses come with the printmaking industry's best 25 Year Warranty. We here at Conrad Machine Co. believe in our products and workmanship, so much so, that we will repair or replace any defects in materials or workmanship for the first 25 years of the life of your printmaking press.