How to Calibrate your Conrad Tabletop Press Micro-gauges

The Conrad Micro-gauge is custom designed to provide the most accurate printing pressure of any press today. Our micro-gauges are cut from solid aluminum to maintain accurate readings. The hand polished finish gives our micro-gauges a clean and elegant look. The Conrad micro-gauge is calibrated to .005 inches. That means you can evenly raise and lower the upper roll of your press about the width of human hair!

All Conrad Micro-gauges are set and calibrated on all Conrad presses before they leave our factory. We realize that many printmakers want to custom set their micro-gauges for different thickness bedplates and printing techniques. Below are instructions for setting the dials on Conrad Micro-gauges.

How to read your Conrad Micro-gauges

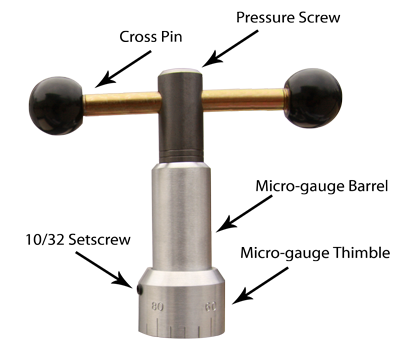

The Conrad Micro-gauge is the most accurate gauge available today. The easy to read dial makes printing with hairline accuracy effortless. Our micro-gauges are designed to measure the distance between the upper roller and the bedplateónot simply count pressure screw rotations. The Conrad Micro-gauge allows you to accurately measure your printing height. The lines on the micro-gauge pressure screw indicate the revolutions of the pressure screw. Each revolution of the pressure screw raises the upper roll .100 inches indicated by the numbers on the dial of the micro-gauge thimble. To calculate the total measurement between the upper roll and the bedplate, multiply the number of lines showing on the micro-gauge barrel, not including the "0" line, by 100 and add that to the number on the micro-gauge thimble.

Assume two lines are showing on the micro-gauge pressure screw, not including the "0" line, and the micro-gauge thimble reads 50. This would indicate that your upper roll is .250 inches above your bedplate. In other words, your upper roll and the bedplate have a 1/4 inch space in between them.

How to set your Conrad Micro-gauges

First, bring the upper roll into firm contact with the bedplate.

Second, loosen the setscrew on the micro-gauge thimble with a 3/32 allen wrench.

Third, slide the micro-gauge barrel up or down until only the top line of the pressure screw slightly appears above the barrel. If for any reason the barrel is not long enough to reach up to the first line, you may set your gauge at the second or third line. Be sure to set both micro-gauges to the same line. It may be necessary to rotate the dial slightly while making this adjustment.

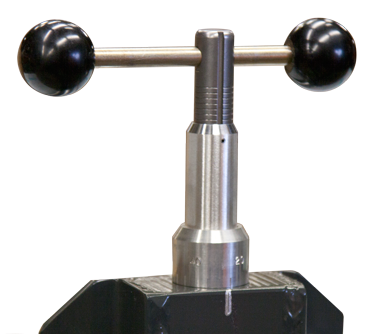

Fourth, rotate the micro-gauge thimble until the zero on the dial lines up with the zero on the top cap of your press frame. The line on the top cap is set at our factory and comes standard on all presses ordered with micro-gauges. If you are installing micro-gauges for the first time, you will need to mark the top cap yourself. This can easily be done with a black marker. Simply draw a line on the top cap in the center of the micro-gauge. If you would like a more permanent line, you can use a chisel to notch a line in the top cap. The line is most conveniently located on the outside of the press frame, so it is easily visible when you are printing. The picture above displays a mark on the top cap machined at our factory and highlighted with a marker.

Fifth, once the thimble is lined up with the line on the press frame, tighten the set screw on the thimble.

Your Conrad Micro-gauge is set! You are ready to start printing with accuracy.